Static stresses

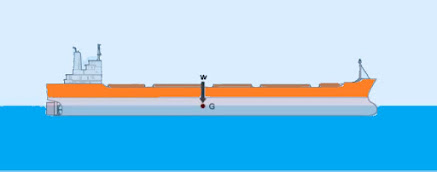

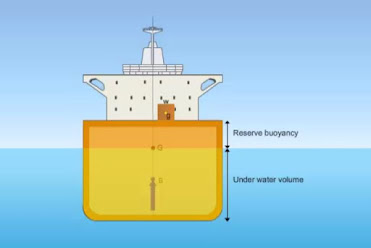

Hogging:

- Longitudinal bending stresses could be caused while loading the ship in still water.

- Hogging is a stress that causes the ship's hull or keel to bend upwards at amidships.

- Look at the effect when the load concentration is more on the ends of the vessel.

- The ship structure bend downwards at the end.

Sagging:

- When load concentration is more at the centre, the structure tends to bend downwards in the middle.

- This action is called sagging.

- The vessel is designed with the certain allowable maximum bending moment and shear forces which are tabulated in the approved ship's stability booklet.

- The loading and distribution of weights will be monitored by chief officer of the vessel according to the prescribed limits with the help of a load indicator and stability booklet.

- He is responsible for minimizing this 'SAG' and 'HOG' of the vessel.

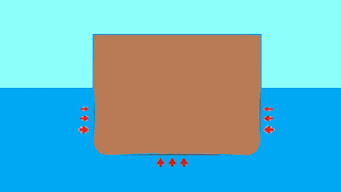

- When the ship is in a dry dock, a ship's sides are no longer supported by water pressure.

- The only things holding the ship are keel blocks, bilge blocks and side shores.

- The result is that the sides of the ship tend to bulge outwards and the bottom tends to sag.

- To counteract drydocking stress, the entire bottom of a ship is strengthened.

- Fluctuation in water pressure causes in and out movement of a ship's side plating at bow and stern.

- This movement results in panting stress.

- It is more pronounced at the bow, which pushes the bow ahead into the water or swell.

- This stress is compensated by fitting panting beams with a distance of two metres between every alternate frames.

- The panting beams are connected to the frames by beam knees and supported by a wash plate at the Centre.

- Side stringers, in line with panting stringers, are fitted throughout this deep framing region.

- Breast hooks fitted to support the radiused stem plate and to prevent in and out movement of the side shell.

- Pounding stress occurs at the bottom plating of a ship near the bow during excessive pitching.

- To compensate slamming down of a ship's bottom, outer bottom plating is thickened and connections to inner shell and inner bottom girder are strengthened.

- The thickness of plates near the pounding is increased by thirty percent and transverse frame spacing is reduced from nine hundred millimeters; to seven hundred millimetres.

- Solid floors fitted at every frame space are welded to the bottom shell and transverse floors are fitted at alternate frames.

Water pressure:

Drydock:

Localised stress:

When a heavyweight is loaded over a small area or if there is a concentration of weight in a particular area, it causes localized stresses.

Localized stress is counteracted by extra strengthening.

Dynamic stresses

Panting stress:

Pounding stress:

Racking stress:

- This stress is more pronounced on the corners of the ship due to wave action on the hull.

- Racking stresses are reduced by fitting beam knees and tank side brackets.

- But the most effective way to resist racking is to fit transverse bulkheads.